My surprise contact yesterday was EA6UN on the Balearic Islands off the coast of Spain in the western Mediterranean Sea. That's over 4600 miles on my five watts. I found Jurek calling CQ on 14.050 MHz with no responses. He came right back to me and gave a 579 report. Today's QSOs have all been to the west...WB6HGJ (CA), W7LPV (AZ) and N6IV (CA).

Thursday, June 14, 2012

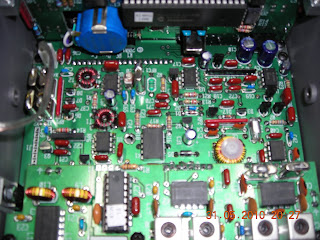

MOBO V4.3.4 SR V6.3 (Original) preparation

I just build a new SR V6.3 from scratch and added the headers for RX and TX IQ and beefed up the power.

I didn't have a 1N5422 but I have a 1N5408 instead and after a quick test then extended the diode PCB pads a little so not as 'tidy' as the little DO41 drop in replacement.

I did a scratch rebuild as the previous build had a LDVS version not a CMOS Si570 in place as a sample chip and could go to >260MHz and as this is for SDR-Radio development I will keep the build to 'vanilla' only.

I noted the MOBO kit seems to have plenty of jumper connectors so will make some up.

I will use a length of RG174 or similar for the RF and I will use some shielded audio cables for the RX & TX IQ.

Wednesday, June 13, 2012

MOBO V4.3.4 PA

I did this:

MOSFET attaches to REAR.

I used a needle file and removed the anodising on the bottom ends of the heatsink and around the TO220 middle mounting hole.

To attach th heatsink to the PCB I used two self threading M3 (ish) screws that bit into the heatsinks and created a good contact (I checked resistance was <0.1ohms). Turned the board up away from you on the right hand side (R30) underneath I used a flat washer and a Computer red insulating washer, on the left hand side I used a flat washer and a star washer that bit into the tinned area. In between the heatsink and the top of the PCB on both sides I placed a star washer.

I secured the heatsink to the PCB first THEN and Only after it was secure did I attach the MOSFET and then checked for conductivity between the ground tab on the MOSFET and GND on he PCB. Once satisfied it was good I soldered the MOSFET into place.

The Heatsink sits about 1/32" off the PCB and it and all mounting hardware is clear of any components..

NB on the (outer edge of PCB) of the TO220 mount I used a brass washer and heat sink compound between the MOSFET and the heatsink, The screw was brass M3. On the reserve side (facing into the PCB) no heat sink compound and I used a star washer and flat brass washer to make a good contact between the MOSFET and the heatsink.